air cleaner for 22r

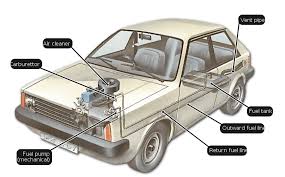

How a fuel pump works Now on your iPhone and iPad! Over 250 detailed articles Instant access, no adverts, no internet needed Just $2.99 for a limited time. Read more essential guides A carburettor mixes fuel and air in the proportions and quantity the engine needs at any time. Powered by your social love!Auto Parts/Auto/Filters/DistancePlus Oil Filters/ See all DistancePlus™ Oil Filters Dry Weight (without muffler) Only Kawasaki Critical Power engines listed on this website have been tested in accordance with SAE J1995, verified by TUV Rheinland Group, and certified by SAE International. The gross power ratings of these engines were determined by using measurements according to SAE J1995 which were witnessed by SAE-approved witnesses from TUV Rheinland Group. Torque ratings of these engines were not certified by SAE. Actual power and torque output will vary depending on numerous factors, including, but not limited to, the operating speed of the engine in application, environmental conditions, maintenance, and other variables.

The gross power rating of the FD620D engine is reference for OEM customers. Kawasaki does not intend this information to accompany the engine and/or the lawnmower at the time of retail sale to a consumer. The gross power rating was determined by using measurements is according to SAE J1995 as rated by Kawasaki, not were witnessed by third party tester. Actual power output will vary depending on numerous factors, including, but not limited to, the operating speed of the engine in application, environmental conditions, maintenance, and other variables. Protect your engine with Ryco Fuel FiltersOil filters work in a multi-pass system that allows engine oil to continually pass through the filter and remove dirt. A vehicle’s entire oil supply is filtered between four and five times every minute and their function is to allow only clean filtered oil through to the engine.Ryco oil filters are designed to meet or exceed the vehicle manufacturer’s specification and provide optimal filtration for the specified service interval.

Ryco achieve this by measuring the three critical areas of efficiency, life and flow.There are two styles of Ryco Oil FilterSpin On oil filters are designed to withstand oil pressure considerably in excess of the highest working oil pressure specified for modern engines that have tighter tolerances and service intervals."Eco" or cartridge oil filters are a replaceable element that fits into a reusable housing. This style of filter design is becoming more common with vehicle manufacturers as they attempt to reduce waste.

car air purifier/ionizer/oxygen barInferior oil filters can inhibit oil flow causing high pressure and clog before the service interval and allow unfiltered oil into then engine.

kent air purifier chennai Secondary air injection (commonly known as air injection) is a vehicle emissions control strategy introduced in 1966, wherein fresh air is injected into the exhaust stream to allow for a fuller combustion of exhaust gases.

honeywell air purifier cigarette smoke

The mechanism by which exhaust emissions are controlled depends on the method of injection and the point at which air enters the exhaust system, and has varied during the course of the development of the technology. The first systems injected air very close to the engine, either in the cylinder head's exhaust ports or in the exhaust manifold. These systems provided oxygen to oxidize (burn) unburned and partially burned fuel in the exhaust before its ejection from the tailpipe. There was significant unburned and partially burned fuel in the exhaust of 1960s and early 1970s vehicles, and so secondary air injection significantly reduced tailpipe emissions. However, the extra heat of recombustion, particularly with an excessively rich exhaust caused by misfiring or a maladjusted carburetor, tended to damage exhaust valves and could even be seen to cause the exhaust manifold to incandesce. As emission control strategies grew more sophisticated and effective, the amount of unburned and partially burned fuel in the exhaust stream shrank, and particularly when the catalytic converter was introduced, the function of secondary air injection shifted.

Rather than being a primary emission control device, the secondary air injection system was adapted to support the efficient function of the catalytic converter. The original air injection point became known as the upstream injection point. When the engine is cold, air injected at this point cleans up the extra-rich exhaust and raises the temperature of the exhaust so as to bring the catalytic converter to operating temperature quickly. Once the engine is warm, air is injected to the downstream location — the catalytic converter itself — to assist with catalysis of unburned hydrocarbons and carbon monoxide. Pumped air injection systems use a vane pump called the air pump, AIR pump, or colloquially "smog pump" turned by the engine via a belt or electric motor. The pump's air intake is filtered by a rotating screen to exclude dirt particles large enough to damage the system. Air is delivered under light pressure to the injection point(s). A check valve prevents exhaust forcing its way back through the air injection system, which would damage the pump and other components.

Carbureted engines' exhaust raw fuel content tends to spike when the driver suddenly releases the throttle. To prevent the startling and potentially damaging effects of the explosive combustion of this raw fuel, a diverter valve is used. This valve senses the sharp increase in intake manifold vacuum resulting from the sudden closure of the throttle, and diverts the air pump's outlet to atmosphere. Usually this diverted air is routed to the engine air cleaner or to a separate silencer to muffle objectionable pump noise. Air injection can also be achieved by taking advantage of the negative pressure pulses in the exhaust system at engine idle. A sensitive reed valve assembly called the aspirator valve is placed in the air injection pumping, which draws its air directly from the clean side of the air filter. During engine idle, brief but periodic negative pressure pulses in the exhaust system draw air through the aspirator valve and into the exhaust stream at the catalytic converter.