air purifier advantages disadvantages

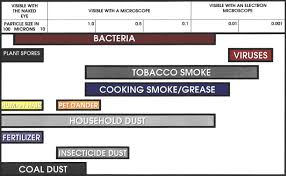

Ultraviolet water purification uses electromagnetic radiation to decontaminate water to be treated. It is only one of the methods used to for water purification. Others include chemical, physical and biological processes. Various chemicals, bacteria and other materials are often present in untreated water. Whether the water is intended for consumption or some other application that requires treatment, water purification is necessary to reduce the amount of contaminants occurring in it. The use of ultraviolet light to purify water has many advantages over chemical methods like chlorination. There is a downside to the process as well which often requires secondary treatment after the fact. Essentially, ultraviolet light is produced by means of a germicidal or mercury vapor lamp made with glass that allows the optimal shortwave ultraviolet light a fully transparent surface through which to pass. The shortwave radiation then comes into contact with the parasite, bacteria, fungi or other microorganism and eliminates it.

Ultraviolet water purification possesses advantages over a more widespread treatment like chlorination. These mostly have to do with the toxicity levels of chlorine. Chlorine requires attention during the purification process while UV purification does not. UV does not contribute to poor-tasting water like chlorine, nor is it chemically active. Chlorine may actually react with other ingredients present and form compounds of a toxic nature.

cyclone air pre-cleaner assemblyUltraviolet radiation does not use heat or chemical additives of any kind during the purification process.

target ionic pro air purifierThe simple fact that it comes into contact with the microorganism is enough to inactivate it and render it harmless.

cleaning air gap ge dishwasher

There are two main disadvantages to speak of about ultraviolet water purification. The first is that the water being treated must be in no way turbid or cloudy. Any level of color present in the water will hinder the ability of the UV radiation to penetrate it and destroy the microorganisms within. This requires water filtration prior to the purification which adds expense to the procedure. Otherwise, much of the UV light is absorbed and becomes largely ineffective. The second main disadvantage is that ultraviolet purification offers no residual treatment. Unlike chlorine which maintains a presence in the water after the treatment, continuing to disinfect the water, ultraviolet radiation does not stay in the water. Any microorganisms that the radiation missed would remain in the water whereas chlorination would destroy them. For this reason, a chlorine compound such as chloramine is sometimes added to water purified by ultraviolet radiation after the fact. Ultraviolet light is an effective means of disinfecting water for consumption, but an additional chemical process is sometimes necessary to ensure that all residual microorganisms are destroyed.

By inactivating bacteria and other harmful particles found in untreated water, UV radiation leaves no chemical side effect. To be effective, however, it must enter relatively clear water so as not to be absorbed. Since ultraviolet water purification does not remain in treated water, a chemical such as a chlorine compound is added to the treated water after the fact. Although this does negate some of the advantages of ultraviolet water purification, it still manages to avoid the potential side effects of chlorination. installation in an HVAC system. Advantages of a central system better clean air distribution, keep central heating/cooling equipment clean and efficient filter outside air before it enters maintenance than portables around the , more cost effective than portables The most direct way to install air filtration equipment in a central HVAC system is to place the equipment directly in the return duct at a common point where all the air is flowing back to the heating and cooling

High efficiency air filters have very high air resistance. result, placing high efficiency filters, such as HEPA filters, directly in the duct, imposes loading on the existing HVAC air handler which the air handler may not be able to adequately overcome. For this reason, lower efficiency, lower loading, ASHRAE type efficiency filters are generally used in line, in duct, as they impose less loading on the existing air handler. The use of high efficiency filters could result in the need for an air handler upgrade and additional cost. An alternative to ASHRAE filters is the use of electronic air cleaners. generally impose relatively low loads on the HVAC air handler making them popular alternatives to high efficiency filters. air cleaners require routine cleaning rather than filter replacement, which is seen by some as an additional advantage. air cleaners will not provide equivalent efficiency as high efficiency

filters such as HEPA filters, as electronic air cleaners usually are rated on a ASHRAE efficiency scale. NOTE: More information about efficiency standards is available. The By-Pass installation of air filtration equipment into an HVAC system circumvents the HVAC air handler loading issue noted in theIn the By-Pass installation, the air filtration equipment intake is connected to a port on the return duct at a common point where all the air is flowing back to the heating and coolingAfter being diverted into the air cleaning equipment and filtered, the clean filtered air is then exhausted back into the HVAC system return duct downstream (closer to the heating and cooling equipment). the air cleaning equipment is properly matched to the air flow in the HVAC return duct, a large portion of the return air will pass through the air cleaner and be filtered. Here for more informationDuctless, mini-split-system heat pumps (mini splits) make good retrofit add-ons to houses with "non-ducted" heating systems, such as hydronic (hot water heat), radiant panels, and space heaters (wood, kerosene, propane).

They can also be a good choice for room additions, where extending or installing distribution ductwork is not feasible. Like standard air-source heat pumps, mini splits have two main components: an outdoor compressor/condenser, and an indoor air-handling unit. A conduit, which houses the power cable, refrigerant tubing, suction tubing, and a condensate drain, links the outdoor and indoor units. The main advantages of mini splits are their small size and flexibility for zoning or heating and cooling individual rooms. Many models can have as many as four indoor air handling units (for four zones or rooms) connected to one outdoor unit. The number depends on how much heating or cooling is required for the building or each zone (which in turn is affected by how well the building is insulated). Since each of the zones will have its own thermostat, you only need to condition that place when someone is there. This will save energy and money. Ductless mini-split systems are also often easier to install than other types of space conditioning systems.

For example, the hook-up between the outdoor and indoor units generally requires only a three-inch hole through a wall for the conduit. Also, most manufacturers of this type of system can provide a variety of lengths of connecting conduits. If necessary, you can locate the outdoor unit as far away as 50 feet from the indoor evaporator. This makes it possible to cool rooms on the front side of a building house with the compressor in a more advantageous or inconspicuous place on the outside of the building. Since mini splits have no ducts, they avoid the energy losses associated with ductwork of central forced air systems. Duct losses can account for more than 30% of energy consumption for space conditioning, especially if the ducts are in an unconditioned space such as an attic. In comparison to other add-on systems, mini splits offer more flexibility in interior design options. The indoor air handlers can be suspended from a ceiling, mounted flush into a drop ceiling, or hung on a wall.

Floor-standing models are also available. Most indoor units have profiles of about seven inches deep and usually come with sleek, high tech-looking jackets. Many also offer a remote control to make it easier to turn the system on and off when it's positioned high on a wall or suspended from a ceiling. Split-systems can also help to keep your home safer since there is only a small hole in the wall. Through-the-wall and window mounted room air-conditioners can provide an easy entrance for intruders. The primary disadvantage of mini splits is their cost. Such systems cost about $1,500–$2,000 per ton (12,000 Btu per hour) of cooling capacity. This is about 30% more than central systems (not including ductwork) and may cost twice as much as window units of similar capacity. The installer must also correctly size each indoor unit and judge the best location for its installation. Oversized or incorrectly located air-handlers often result in short-cycling, which wastes energy and does not provide proper temperature or humidity control.