biozone 2000 air purifier review

FM Industry Publications SA Facilities management journal march 2015 The 'must have' publication for all facilities managers in Southern Africa Discover a good night’s sleep with mattress toppers from Harris Scarfe. Browse ball fibre, microfiber, latex, memory foam mattress toppers for a little bit of luxury in your bedroom. Ramesses 1200 sherpa mattress topper kb Ramesses 1200 sherpa mattress topper qb Ramesses 1200 sherpa mattress topper db Ramesses 1200 sherpa mattress topper sb Alastairs soho luxury topper kb Alastairs soho luxury topper qb Alastairs soho luxury topper db Alastairs soho luxury topper ksb Alastair's Soho Luxury Topper SB Tontine I Need A Fibre Fresh Topper KB Tontine I Need Fibre Fresh Topper QB Tontine i need fibre fresh topper db Tontine I Need A Fibre Fresh Topper SB Soren High Loft Mattress Topper KB Soren High Loft Mattress Topper QB Killarney Superloft Microdown Topper QB

Killarney Superloft Microdown Topper DB Killarney Superloft Microdown Topper SB Phase 2 Cloud Soft Mattress Topper QB Phase 2 Cloud Soft Mattress Topper DBThe modular treatment systems are designed to meet site specific requirements and can be configured to meet various population sizes and to meet demanding, individual site requirements. The package offers complete in-house design and specification service including a turnkey service of initial site survey, commissioning and project liaison if required. Suitable for larger applications and manufactured from glass reinforced plastic (), the system is installed below ground. Low running cost and maintenance The design has no internal mechanical moving parts therefore the plant requires minimal annual maintenance Emptying of the tank is also not required during maintenance of air distribution system Low installation costs and flexibility on site Only a small excavation is required due to its compact design allowing flexibility of positioning on site

Energy saving options and chemical dosing packages can be configured to the design for site specific requirements Does not impede views due to the below ground installation

rsd blunt air cleaner Variable flows and loads

air purifier eligible hsa The unique design of the flow balancing in the primary tank means it can cope with variable flows and loads

therapure tower air purifier review Robust operation and stand-by facility Safe, clean, accessible air diffuser system with large access lids for easy maintenance Humus and primary sludge are stored in one place for simple tankering operation Tank 25 years life GRP is UV stabilised with an external gel coat finish which extends the asset life to 25 years

WPL HiPAF plants and kiosks are produced in a quality controlled environment at the WPL factory WPL tailor our robust and reliable solutions to meet our clients’ demanding specifications and expectations. Typical Commercial Uses Include: Animal waste options such as stables and kennels Agricultural growers and garden centres Camping and caravanning sites Golf courses and fishing lodges Hotels, restaurants and public houses Care homes and retirement villages Commercial buildings and offices Schools, colleges and training centres Stately homes and large country estates Villages and rural communities Zoos, theme parks and leisure attractions and leisure centres The WPL HiPAF Modular Standard The WPL HiPAF modular range meets the following industry standards: Fully compliant with UK Building Regulations and Environment Agency (EA) guidelines The WPL HiPAF is designed using the British Water Code of Practice Flows and Loads, to ensure correct sized tanks

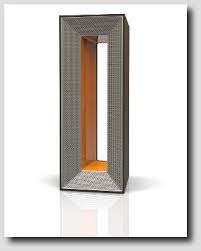

Designed to BS EN 12255 – 1/15 and manufactured using BS 4994 The HiPAF modular plant can be configured with additional options to meet design for site specific requirements: WPL Balancing Tanksshould be considered when sites have variable occupancy levels, such as sporting and wedding facilities InstallingWPL RADScan reduce de-sludge frequencies on the biological treatment plant by 75% offering extended de-sludge intervals WPL Sand Filterscan improve final effluent for strict consent requirements WPL can supply aduty/standby blowerswith automatic change over to ensure an uninterrupted air supply and maintain high levels of treatment Energy saving options such asvariable speed drive blowers available Standard kiosk design for commercial applications Each HiPAF comes complete with a discreet, weatherproof, acoustically lined GRP kiosk, situated above ground. This houses the blower(s), a Form 2 control panel and air distribution manifold.

Included as standard is 10m of airline, to connect the blowers to the tank. Blower and airline upgrades are available if the kiosk is sited further than 10m from the plant. The Form 2 control panel, automatically controls the operation of the plant. Form 4 is also available. Kiosks upgrades available on request e.g. walk in kiosk. MK2 lids for commercial application: All lids are lockable Large lids for easy access to each zone Assisted lifting with gas struts Fully serviceable due to easy access Easily removable air diffusers Optional safety grating when in place prevents risk of fall The HiPAF Treatment Process Primary– Primary settlement is in accordance with EN12255-4, giving the required hydraulic retention time and ensuring that 30% of the BOD will settle out in the primary tank. WPL HiPAF plants below 500 persons will have sludge storage integral to the primary tank. The primary settlement tank is equipped with baffles to prevent floating scum entering the biological phase of the treatment process.

It also incorporates WPL Limited’s unique forward feed system which lowers the level in the tank, during periods of low flow, to provide a buffering capacity for possible surges in the. Biological– After primary settlement, the settled liquor flows to the biological treatment unit by displacement and via the air lift forward feed. The biozone is fully segmented internally to eliminate the risk of process short cuts. Each biozone segment is filled with high voidage plastic filter media, where both carbonaceous and nitrifying processes take place, mitigating process risks associated with variable loads. Air to oxygenate the influent and to scour excess biomass from the filter media is introduced continuously below each chamber by a series of diffusers. Final– Following biological treatment the effluent flows into the final (humus) settlement tank where the excess biomass settles out. The humus tank is equipped with air lifts which are arranged to automatically transfer settled humus sludge to the primary tank for co-settlement.