mass air flow sensor cleaner napa

HomeShop by ProductOther ProductsCleaners and Protectants Save up to 25% or Product Highlights View Full Description Improves engine performance by removing gum, varnish and carbon deposits that affect power, operation, idle and fuel economy. Power Foam cleans intake valves, intake manifolds and throttle plates to keep the combustion intake system running at peak efficiency. Helps reduce engine ping and keeps carburetors and injector systems operating like new. **NOT AVAILABLE IN CANADA**NOT AVAILABLE IN CALIFORNIAAMSOIL Power Foam® (APF) improves engine performance by removing gum, varnish and carbon deposits that affect power, operation, idle and fuel economy. Effective in both two-cycle and four-cycle gasoline engines, AMSOIL Power Foam helps reduce engine ping and keeps carburetors and injector systems operating like new. Power Foam is safe for fuel injectors, catalytic converters and emission control devices. It will not damage seals, gaskets, rubber or plastic materials commonly used in gasoline engines.

Performance FeaturesCleans deposits from ethanol and degraded fuelRemoves gum and varnishMaximizes horsepowerRestores startabilityHelps improve fuel economyReduces pollutionApplicationsUTVs/ATVsBoatsMotorcyclesLawn EquipmentTractorsAutomobilesDirectionsProtect painted surfaces and mass airflow sensors (MAF) from spray.

sears air duct cleaning reviews njEnsure application is in a well-ventilated area.

air purifier with hepa singaporeRun engine to normal operating temperature and remove air cleaner assembly.

air duct cleaning northbrook ilWhile engine is running, spray foam directly into throttle body as fast as possible without stalling engine.Shut off engine and allow to sit for 10-15 minutes.Repeat application of Power Foam as needed.

In extreme cases, disassemble carburetor and soak parts.RecommendationsAvoid contact with hoses and exterior plastic components. To prevent the dissolving of paint, do not overspray. AMSOIL Power Foam is not recommended for use in diesel engines or as a general purpose degreaser.AMSOIL PRODUCT AVAILABILITYAMSOIL Power Foam is available in 18-ounce spray cans. AMSOIL products are backed by a Limited Liability Warranty. This product is not expected to cause health concerns when used for the intended applications and according to the recommendations in the Safety Data Sheet (SDS). An SDS is available or upon request at (715) 392-7101. Keep Out of Reach of Children. Recycle used oil and bottle. For More Technical Information, click here to download the product data bulletinBG Products, Inc.BG Products, Inc.BG 44K® Fuel System Cleaner BG 44K® is the number one fuel injector cleaner! In a recent survey, dealership service managers chose BG 44K® 6 to 1 over the next aftermarket supplier.

Gasoline quality is inconsistent. And when gas at the pump is poor quality, it can cause deposit buildup, inefficient ignition and combustion and poor power output. To make matters worse, small, high output engines are extremely sensitive to deposits that build up on fuel injectors, intake ports, on intake valves and in combustion chambers. Even small amounts of deposits cause increased exhaust emissions, reduced fuel economy, drivability problems and engine knock.BG 44K® is 11 ounces of high quality detergents and additives that you pour right into the gas tank to restore performance and gas mileage. It vanquishes deposits in combustion chambers, intake manifolds, ports and on valves and restores flow in fuel injectors. Basically, it cleans the entire fuel system!Restores performanceRestores fuel efficiencyIncreases power output BG Fuel/Air Induction ServiceJust one can of BG 44K® in your fuel tank can boost your car’s performance, but for a more thorough fuel system service, get a BG Fuel/Air Induction Service including BG 44K®.

Find a shop near you that offers BG 44K® and the BG Fuel/Air Induction Service!BG Fuel/Air Induction Service is backed by the Lifetime BG Protection Plan™ if the initial service is performed within 75,000 miles/120,000 km. To maintain coverage, get a BG Fuel/Air Induction Service every 15,000 miles/25,000 km!PN 208 11 fl. oz. (325 mL) canPN 20811 11 fl. oz. (325 mL) bottlePlease read the disclaimer page Please visit our FORUM. All discussion, questions and comments about this article are welcome. Ever since we finished our oil filter study, we have wanted to follow it with a companion study examining at the often overlooked air filter and some of the available options out there and how they fare against each other in both their airflow and filtration abilities. Please note, this study is not, and does not claim to be a replacement for ISO filter testing. This study is designed to test the claims made by the various manufacturers, as well as to examine some of the rumors surrounding air filters.

We have no brand affiliation, all the raw data that was collected during the study is presented just as it was recorded. Full Disclosure statement: This study has in no way been funded by any filter brand or company, and GM Truck Central, has not received any compensation from any filter brand or company for conducting this study. Individual members have contributed to help cover the cost of the study, but these contributors are individuals and their help has not colored the results we obtained. We have neither brand preferences nor affiliations. Now on to the study. Each filter was tested in a few ways. We took a quick look at the construction, we tested their airflow, and examined their filtration ability. All the filters collected were for the same application to level the playing field between them. The application used was for a 1996 C1500 with a 5.7L L31 Gen1e Vortec small block Chevy. We started with a quick visual inspection on the basis of construction, however, due to the variety of media materials being reviewed (some of which cannot be compared with others, such as foam vs paper), and further testing that is needed, things such as surface area, volume, and other destructive measurements were not taken.

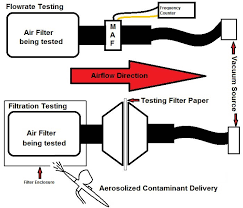

This is inconsequential though, mainly because for the most part, the general construction of the filters was good, there were a few exceptions which are noted in those specific filter pages. For testing the airflow, we constructed an apparatus where the filter is affixed to one end, the other is a vacuum source which was provided by a 5hp vacuum. The airflow measurements were taken using a mass airflow sensor (MAF) from a 1996 C1500 5.7L L31, the same application that the filters were collected for. The MAF sensor outputs a square wave frequency which correlates to the air flow rate, the MAF sensor was powered by a conditioned and regulated power supply, and the output frequency was read using a frequency counter, each filter was tested individually. For testing the filtration ability, a similar apparatus was used with the same vacuum source, however the MAF section of the build was replaced with a section that holds and seals an 8”x10” lab air sampling filter paper. The air filter was then mostly enclosed around to simulate the air filter box with a small opening to allow the airflow and the contaminant introduction.

The contaminant used was a standardized 5µm spherical aluminum powder. This is a VERY fine powder, and was used to try and simulate a ‘worst case scenario’ to get a better differentiation between the performances of each filter. The contaminant was aerosolized and introduced to the airflow using an ‘air eraser’ tool, however the normal operating pressures of the air eraser were lowered from 90psi to 30psi and held at a distance of approx 8 inches from the filter surface, this is because we did not want to force the particles through the filter, but rather just aerosolize them enough to let the vacuum pull the contaminated airflow through the air filter being tested, then through the lab filter paper. The filtration ability was measured with a precision scale (accurate to .001g) to measure the amount of contaminant being introduced, as well as the air filters and the lab filter papers both before and after the test to measure the amount of contaminant that the air filter collected, as well as the amount of contaminant that was passed through the air filter and collected by the lab filter paper.

The lab filter papers used were very high efficiency air sampling glass fiber filters that are 99% efficient at 1µm particles. The lab filter papers were photographed after all filters were tested, however the fine particles of the contaminant which would just build up layers on top and showed minimal distinction between the filters from a visual standpoint, with exception of the very best filters. So the photographing of the lab papers is simply for something to look at and not necessarily to be used for the comparison between them. Unfortunately I was unable to get any photographs of the actual apparatus that was used for the testing, however the diagram below shows the general build that is being described. So we will go over the results in general first, and follow that where you can view the notes and specifics for individual filters. In regards to the airflow of the filters, the data collected from each filter was very similar with minimal changes between each regardless of filtering media or style of filter being tested.

The frequency measured was averaged over approx 30 seconds for each filter (at 5MS/s), however the frequency data would fluctuate as much as a total of 800Hz (+400Hz, and -400Hz) for each filter, so the slight differences seen between the filters is basically inconsequential, and within the tolerances of every other filter. The graph below shows the filter frequency collected data on the blue line, the red line is the frequency averaged between all the filters, as you can see the black error bars encompass the average frequency for every single filter. My conclusion with regards to airflow is that choosing a filter type or style for ‘more flow’ for either performance, or fuel mileage, is useless. The benefits of simply changing from a dirty filter, to a clean one, will give more benefit, than just changing from one filter style to another. The filtration testing gave much more conclusive results though. The data collected shows a clear benefit to some filters over others.

Basically, what we are looking at is the measurement of the contaminants that are both captured by the air filter, ideally this will be as much as possible. We’re also looking at the amount of the contaminant that the air filter allows to be passed through the media and is then captured by the lab filter paper, ideally this value will be as small as possible. When we organize this data as a percentage of contaminant that passed through the air filters, the filters that are more efficient will result in a lower percentage (low contaminant passed), as you can see from this graph which shows the best filtering filters on the left, and the worst on the right. You can see a huge variance between the filtration ability of the filters with the Amsoil doing exceptionally well, as well as the Napa, Wix, and others doing very well also, you’ll also see some doing poorly like the K&N, and Trueflow foam filter. Note: The procedure for introducing the contaminant by aerosolizing it does result in a loss of some of the introduced contaminant, for example, some of it doesn’t get pulled into the vacuum of the filter airflow, etc.

The average contaminant that was introduced to each filter was 6.509g, with the average lost contaminant being approx 1.2 g, this lost contaminant is not ideal, however when dealing with aerosolized particles, under the control we have, it is unavoidable. Keep in mind, this lost contaminant was removed from the calculations for each of the percentages in the previous graph, so that data contains only the relevant contaminant data. The following graph shows the different amounts of contaminant collected, which shows the variation in the blue line resulting from the lost contaminant, as well as the trends, organized the same as the percentages graph above. You can see that the trend lines for both the contaminant passed, as well as the contaminant stopped, are converging at a very similar rate (slopes of the trend lines). These trends show that the amount of captured contaminant is related to the amount of contaminant passed, which is what we would expect to see, the more contaminant is let through the media, obviously the more will be collected on the lab filter paper, which back up the study results.

One thing worth noting on here is in the difference of media. There was a wide variety tested, from fiber, synthetic fiber, gause, and foam. There were also oiled and dry variations of these medias as well. One thing I thought was interesting is that all the oiled media filters, regardless of what the media type was, performed worse than the dry filters. In fact, the last 4 filters on the chart, the pure one, fram, K&N, and Trueflow, are all of the oiled filters, the rest are all dry versions of various media materials. While with only a small sample size, we can't say that all oiled filters are worse than dry filters, but from the data we saw, it is worth noting their placement. My conclusion from all of this is to choose your filters based on filtration ability and cost, and not to expect a performance benefit from one filter brand to the next. We received a bit of feedback from the oil filter study about including the filter prices in our price to performance comparison, since prices can vary based on location and other factors.